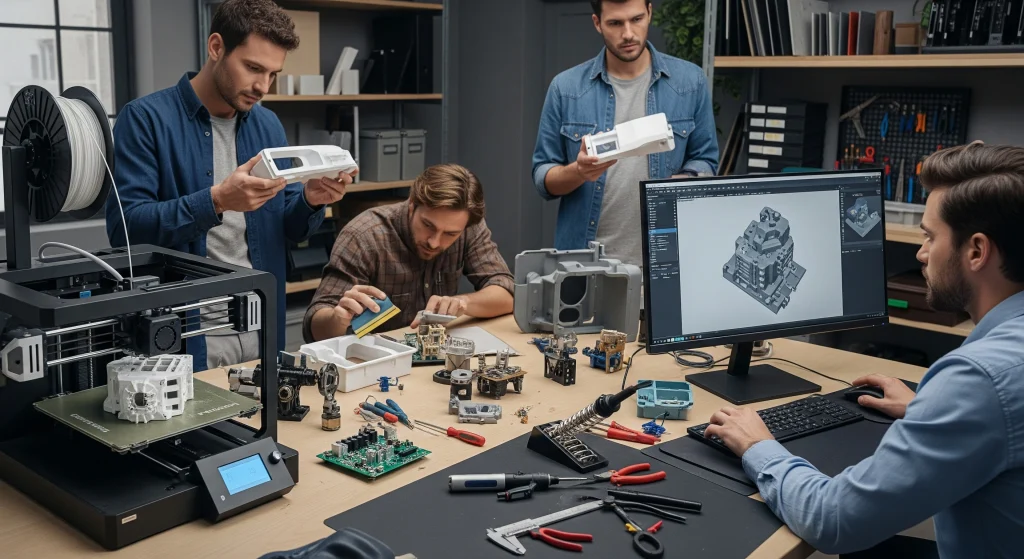

Engineers can now turn digital ideas into real models in just a few days instead of months, thanks to rapid prototyping. This has completely changed how things are designed and made. Designers can 3D print, machine, or cast parts overnight, hold on to them in the morning, and make changes to the design right away. This way, they don’t have to wait weeks for tools that were outsourced.

This piece explains what fast prototyping is and why it’s important for US companies. It also shows how NBY IT’s advanced 3D services can help companies, engineering teams, and startups at all stages of the innovation process. You will know everything about rapid prototyping by the end, such as what it is, how it works, how it can help businesses, and how to service it.

What is Rapid Prototyping?

These manufacturing techniques are called “rapid prototyping,” and they make it easy to quickly turn computer-aided design (CAD) files into real models. This lets designers check how things look, fit, and work before they spend a lot of money on tools. Digital data is often used to make scale models in rapid prototyping, according to Autodesk. This is done with 3D printing, which is also known as additive manufacturing. Engineers can use this right away and at a low cost.

The terms “additive manufacturing” and “rapid prototyping” are not the same thing, but many people use them that way. Additive manufacturing is used in rapid prototyping, a quick way to make prototypes by adding, removing, and pressing materials together. Digital fabrication technology can speed up the making process and help companies get ahead of the competition.

Evolution from traditional prototyping

Before, making a prototype required specialized machining, injection molding, or tooling that was expensive, took a long time, and required a lot of skill. Mark Forged says that engineers can now test designs more quickly and more affordably thanks to 3D printing, which gets rid of the long lead times and high costs of traditional prototyping. Digital tools like 3D printing enable rapid prototyping, allowing designs to be produced quickly without the need for die sets or tools. Because of this, months of work are cut down to days because changes are made as soon as feedback comes in. This means that expensive tools are no longer needed to make new products.

Types of Rapid Prototyping

Different types of prototypes are needed at different stages of making a product. Autodesk says there are four types of prototypes: engineering prototypes, prototypes that look like the real thing, prototypes that work like the real thing, and proof-of-concept models. Engineers can pick the right level of authenticity and production method if they know a lot about these groups.

Proof of concept prototypes

These easy-to-make models test the main ideas behind the design. They often don’t care about how things look in the end, but how they work or how they are set up. A low-fidelity proof-of-concept build early on lets teams find big problems before they spend more money.

It looks like they are prototypes

There are prototypes called “lookalikes” that work, feel, and look like the real thing. Designers use them to see how well they work with people, how appealing they are to the market, and how they look. Multijet fusion and stereolithography (SLA) are two processes that produce high-resolution models suitable for visual presentations.

Prototypes that work like

operates-like models replicate the mechanical functioning of the product. Engineers are able to verify motion, assembly, and performance even in the absence of completed materials or finishes. Selective laser sintering (SLS) and fused deposition modeling (FDM) are two methods for creating robust components that can withstand functional testing.

Engineering prototypes

Prototypes in engineering blend form and function. They are often made with more complex materials (e.g., metal powders, thermoplastics, or nylon powders) to mimic finished objects. These prototypes support rigorous testing, regulatory approval, and pre-production validation.

Core Technologies Used in Rapid Prototyping

Both additive and subtractive manufacturing techniques are used in rapid prototyping. Because additive technologies can produce parts directly from digital models with less waste, they are more widely used. Nonetheless, subtractive and casting procedures are equally significant.

Methods of additive manufacturing

A thermoplastic filament is melted and laid down in layers using extrusion in the Fused Deposition Modeling (FDM) process. Although its resolution isn’t as high as that of other technologies, it’s inexpensive and ideal for proof-of-concept prototypes.

Photosensitive resin is cured in thin layers using a laser in stereolithography (SLA). This creates smooth surfaces and fine details. SLA is excellent for creating display models and lookalike prototypes.

Selective Laser Sintering (SLS): This technique uses a laser to fuse nylon powder.

Metal powders are melted or fused using Direct Metal Laser Sintering (DMLS) or Selective Laser Melting (SLM) to create metal parts one layer at a time. These procedures create production-grade, fully dense parts for engineering prototypes and small-batch manufacturing.

Other additive techniques include binder jetting, which combines a liquid and powder agent, digital light processing (DLP), which uses projected light to harden resin, and laminated object manufacturing (LOM), which cuts and joins layers of paper or plastic.

Techniques that increase and decrease pressure

While subtractive techniques like CNC machining and compressive techniques like casting or molding are also crucial, additive manufacturing is very popular. Currently, 3D printing is unable to match CNC milling in terms of accuracy and material selection. Without purchasing pricey equipment, you can quickly create copies of production parts by casting prototypes in silicone or polyurethane. Hybrid approaches combine additive and subtractive procedures to provide you with the best of both worlds.

Rapid Prototyping Process

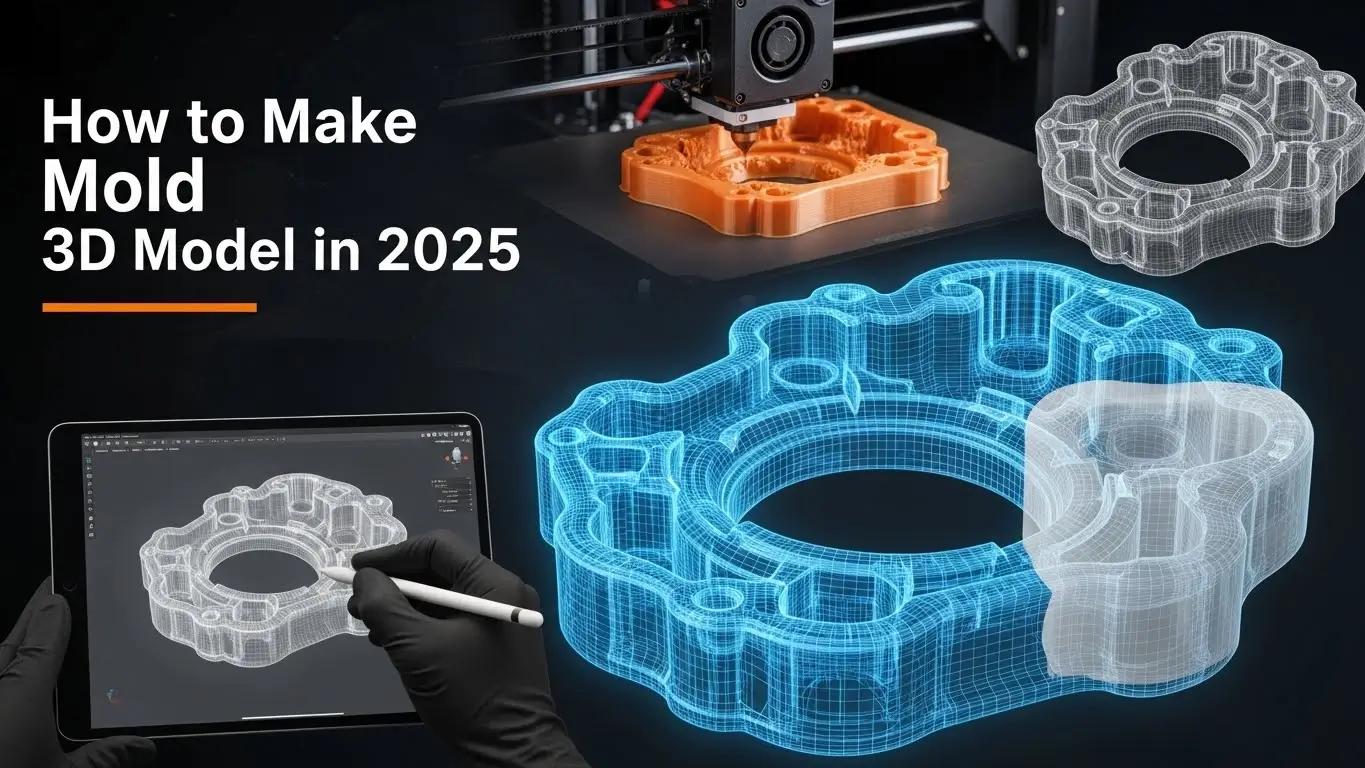

- Design: Engineers make a 3D model using CAD software powered by advanced 3D modeling. The model is tested and improved for production digitally.

- Fabrication: The CAD file is sent to a 3D printer or other manufacturing machine. BigRep says that the printer builds the model layer by layer using the digital geometry as a guide.

- Post Processing: Depending on the process, parts may need to be machined, sanded, cured, or have their supports removed. Some metal parts may need to be heated, whereas nylon or resin parts need to be cured.

- Iteration and testing: The group checks to see how well the prototype works, fits, and looks. We make changes to the CAD model based on what people say. Piocreat says that 3D printing makes real-time refinement possible because it can make working models in only a few hours or days.

- Designers continue making changes to the prototype until it meets the needs for user experience, cost, and performance. Finding design faults early saves time and money later on.

This cycle lets teams from different departments work together quickly, cutting months of work down to weeks or days.

The Benefits of Rapid Prototyping

Faster time to market

Rapid prototyping cuts down on the time it takes to build a product by a lot. Stratasys says that 3D printing can help teams get products to market faster by cutting down on post-processing and time-to-part by up to 90%. Protolabs says that rapid prototyping lets engineers quickly turn CAD files into real parts and lets them test and develop without any delays. Shorter feedback loops lead to getting to market sooner and making changes more quickly.

Lowering risk and saving money

It costs a lot to update the design because traditional tools are so expensive. Rapid prototyping has very little setup, and parts can be made on demand. Protolabs says that 3D printing is cheaper since it needs less setup, fewer steps in the process, and components can be made on demand. Creatingway says that rapid prototyping decreases risks by allowing for more extensive testing, second viewpoints, and faster development timelines. Lowering the cost of molds decreases the financial risk if the design needs to be changed.

Complex geometries and Design Flexibility

Additive manufacturing makes it feasible to make complicated designs that would be hard or impossible to make with traditional methods. Stratasys says that quick prototyping makes it possible to do topology optimization and look into complex geometries. Xometry says that engineers can make internal channels, lattice structures, and lightweight parts by employing additive procedures like SLS and SLA to make net-shaped parts that don’t need much finishing. This independence encourages new ideas and better performance.

Better Collaboration and communication

Using physical prototypes makes it easier for designers, engineers, marketers, and clients to talk to each other. BigRep says that rapid prototyping helps people work together and communicate better. A physical model makes it easier for non-technical stakeholders to give input and makes marketing and sales presentations more powerful. Teams can cut down on misunderstandings and speed up decision-making by focusing on real models.

Customization and individualization

Rapid prototyping makes it feasible to customize things a lot. Stratasys said that 3D printing lets firms make things that are exactly what customers want without raising prices. This feature can help with custom parts, consumer goods, and medical devices. Customers can buy prototypes and custom parts, and changes can be made quickly to match their demands.

Less waste and greater sustainability

Purvis says that 3D printing consumes less energy and makes less trash than other methods. Additive methods only employ the materials needed to make the part, and digital workflows cut down on the amount of inventory and transportation needed. As sustainability becomes a market necessity, rapid prototyping’s efficacy aligns with business environmental goals.

How Rapid Prototyping is Used in Business

Rapid prototyping is employed in more than one industry. It encourages new ideas in many American industries:

Automotive and transportation

Automotive experts use fast prototyping to test engine parts, make dashboards and other interior parts, and check how well the car moves through the air. Protolabs says that rapid prototyping speeds up design cycles and cuts down on the need for automakers to spend a lot of money on redesigns. Piocreat shows how to check the fit and function of engine parts and turbine blade prototypes.

Military and planes

Before spending a lot of money on production, aerospace companies make lightweight parts and test complex assemblies. PA+CF and ABS+CF are two high-performance materials that are strong and can handle heat. Rapid prototyping also aids the aircraft manufacturing business by making jigs and tools faster.

Medical care and health

Companies that make medical equipment quickly improve the designs of implants, prostheses, and surgical tools. 3D printing lets you make models of patients that are specific to them for planning before surgery. According to Protolabs, digital manufacturing makes the whole product lifecycle easier, from idea to production. This means faster iterations and less waste.

Electronics and goods

Rapid prototyping helps new businesses and companies that make consumer goods make things like electronics cases, kitchen appliances, and wearables look and feel better. Getting feedback from customers early on through prototypes lowers the risk of expensive recalls later on.

Robots and machines are used in factories.

Robotics businesses make functioning prototypes of grippers, joints, and housings to see how well they work and how long they last. Protolabs stresses how important rapid prototyping is in robotics by making it easier to develop components and make changes quickly.

Teaching and research

Research laboratories and schools employ rapid prototyping to teach design thinking and manufacturing techniques. Piocreat said that institutions utilize 3D printers to help students be more creative and let them try out complicated parts. Rapid prototyping makes engineering more accessible to everyone by giving researchers and students access to the latest technologies.

Conclusion

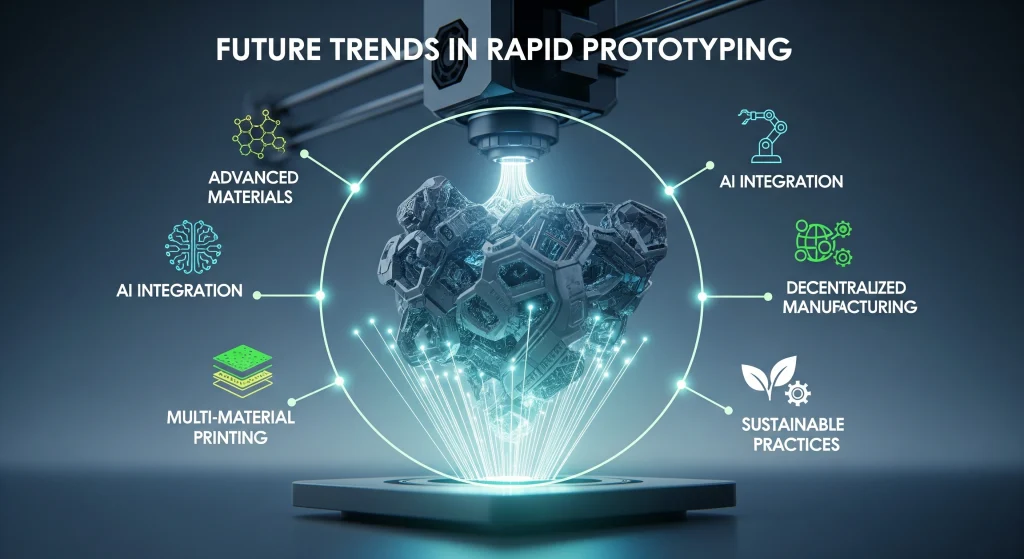

Rapid prototyping slashes product development time from months to days using 3D printing and advanced fabrication. It cuts costs, risks, and waste while enabling complex designs, rapid iterations, and seamless collaboration across automotive, aerospace, healthcare, robotics, and more. Get expert rapid prototyping—from concept models to functional parts—to help US startups and teams innovate fast and stay ahead. Contact us today to turn ideas into reality.