3D printing technology is quite popular in today’s era, it transforms production or manufacturing by building products layer by layer from digital models, in this technology plastics, metals, and resin materials are used to get the desired result. This creative technology allows quick prototyping, modification, and the development of mixed patterns. As a result, it is becoming a game-changer tool for various industries, such as e-commerce platforms, aerospace, healthcare, consumer goods, etc.

What is 3D printing?

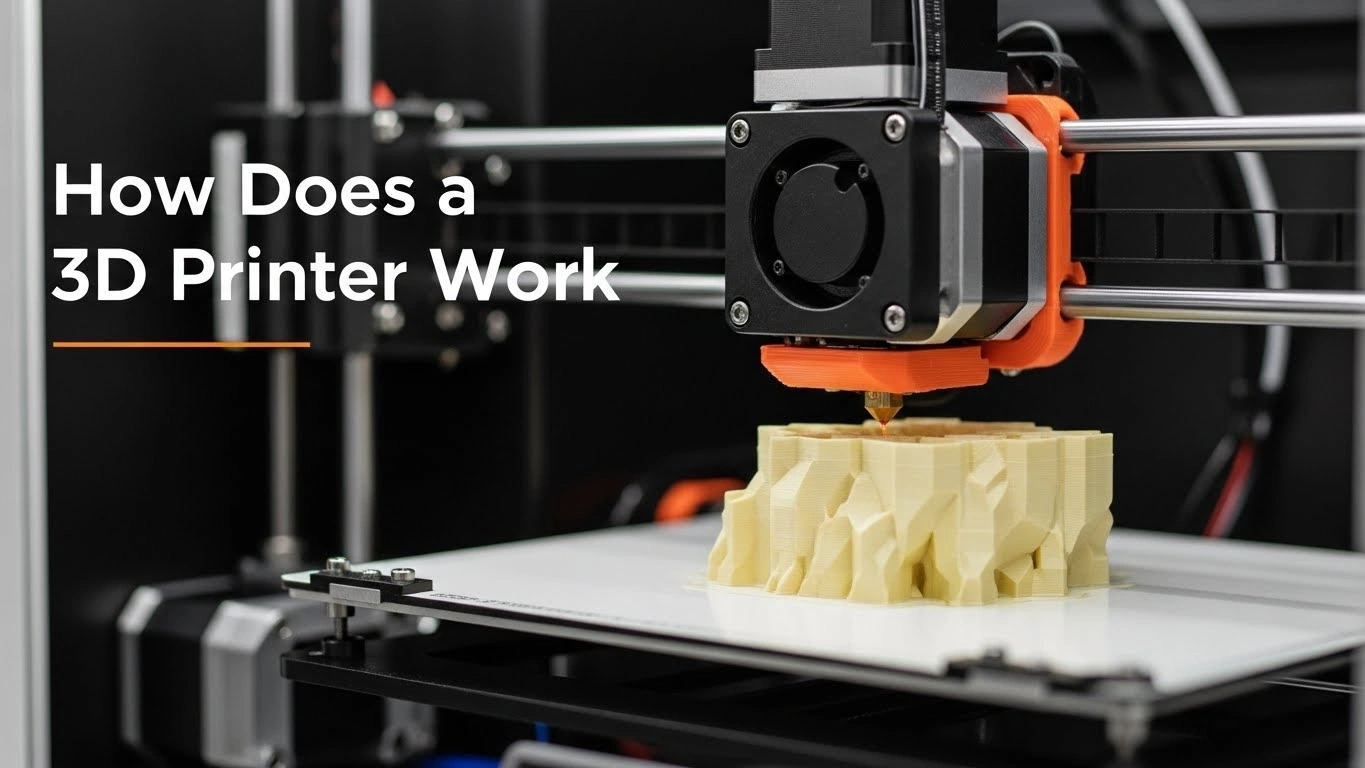

How Does a 3D Printer Work: 3D Printing, short for Three-dimensional printing also known as additive manufacturing, is the action or process to create a physical object from a digital design. The production of a 3D-printed object is done by using additive procedures. An additive method involves laying down multiple layers of material until the product is perfectly created. Each of these levels represents a thinly sliced cross-section of the object.

Hideo Kodama, Raytheon, Bill Masters, and Chuck Hull pioneers in the 1980s laid the framework for these technologies. By the 1990s, metal additive manufacturing technologies had been revealed. In the early 2000s, there was a massive change in availability and collaboration in the 3D printing area. Various Projects such as the RepRap Project and Fab@Home motivated open-source design that allows people and small businesses to build their 3D printers and share inventories.

By the 2010s, the popularity of 3D printing was increasing rapidly. In the 2020s, it became more available to the public. In 2024 the first rise of the world’s largest 3D printer at the University of Maine demonstrated to the world the extensive progress and the ability to manufacture large-range things using additive manufacturing technology.

How Does a 3D Printer Work?

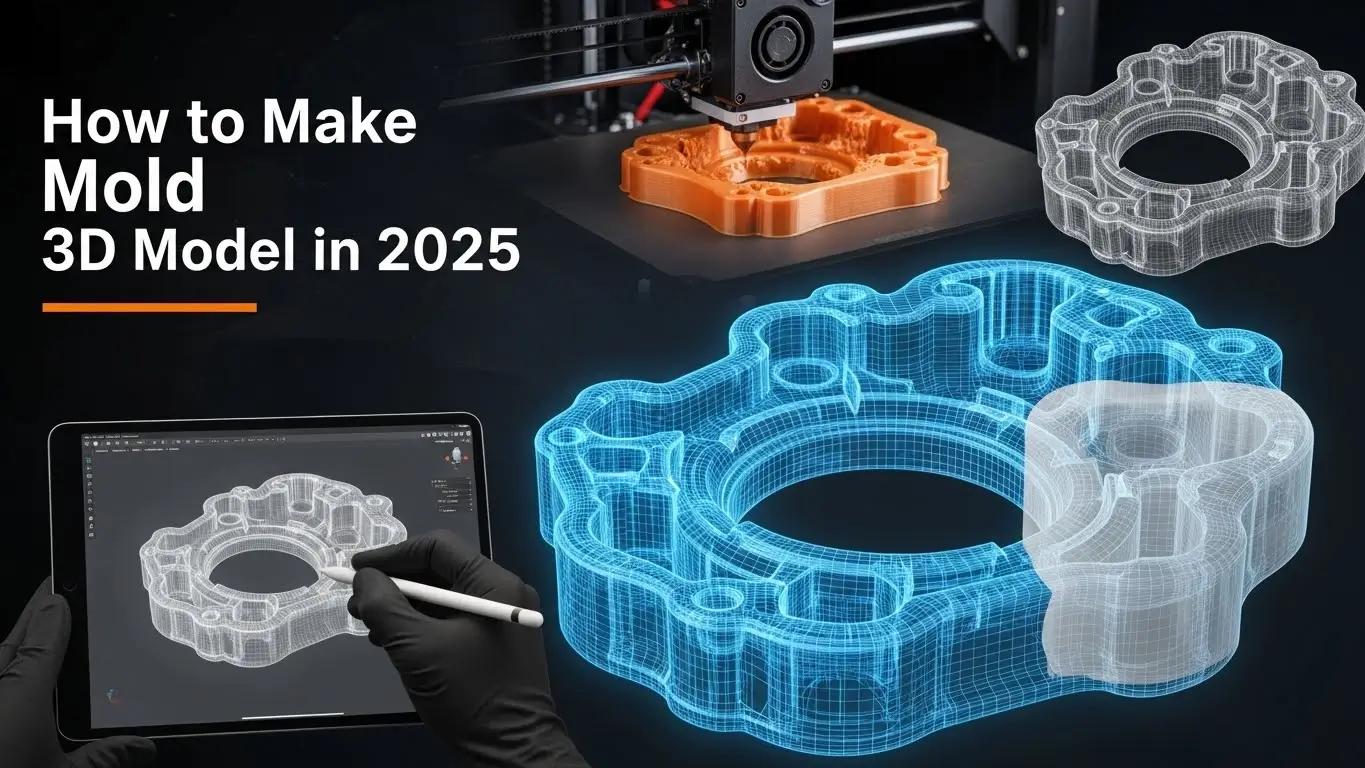

Designing the Model:

First, the user must create or download a digital 3D model of the things they wish to print using computer-aided design (CAD) software, or they can scan the object they have with 3D scanning technology.

Set Up the Printer:

After finalizing the model, one must install and set up the printer. This includes inserting the right printing material into the machine and ensuring all settings are set according to the specified parameters.

Printing the Object:

The printer uses the digital model to apply or melt material layer by layer onto the build platform, and finally create the object as per the design.

Post-processing:

After printing, the object may require additional actions to improve its outlook or functioning. To get the desired result, it may be necessary to remove support structures, sand, paint, or apply other finishing touches.

Applications of 3D Printing Across Different Industries

3D printing technology has rapidly transformed different types of industries. Especially in the Automotive industry, Medical Industry, Aerospace Industry, and many garments Industries.

Automotive Industry

The automotive industry applies 3D Printing to make their work easier in some particular complex areas, they need to produce many complex parts of a product, or they need realistic photos and 3D car modeling or other objects to present in the market or to their audiences, with the help of 3D printing services they can make detailed prototypes of a product for manufacturing.

Medical Industries

Medical Industries usually need 3D printing to create customized implants, artificial objects, and various kinds of anatomical models. Which makes medical study patterns easier.

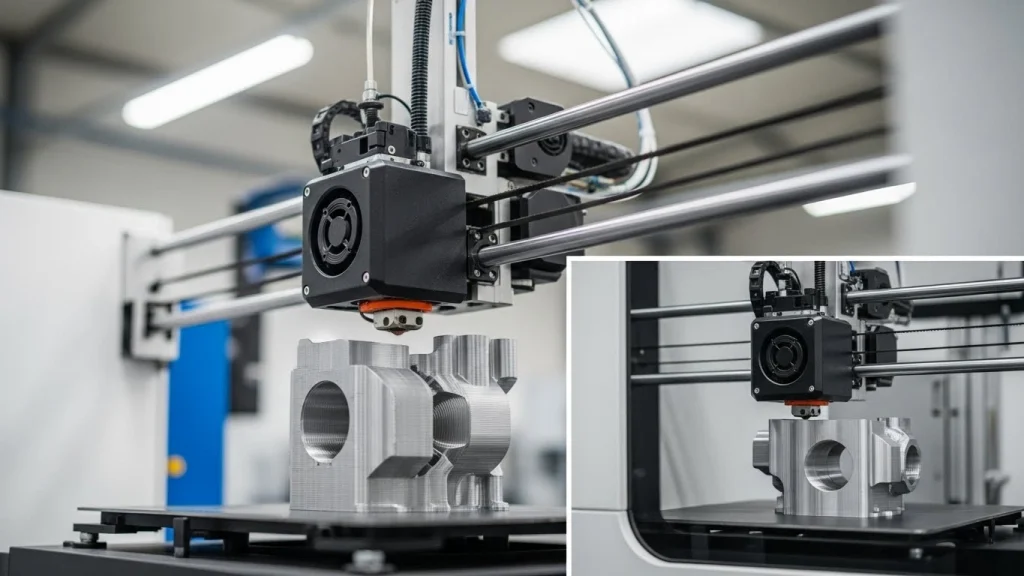

Aerospace Industries

Aerospace companies utilize 3D printing for several 3D product modeling related to their works, such as making lightweight, high-strength objects important for aircraft and spacecraft.

Other Industries

Other industries like various kinds of E-Commerce Platforms, groups of companies, and garments sectors are rapidly using 3D Printing Services for marketing their products and brands more attractively. They demonstrate their products properly to their targeted audiences with 3D Modelling Services. They need 3D printing services to display their products in detail to the customers.

Types of 3D Printers

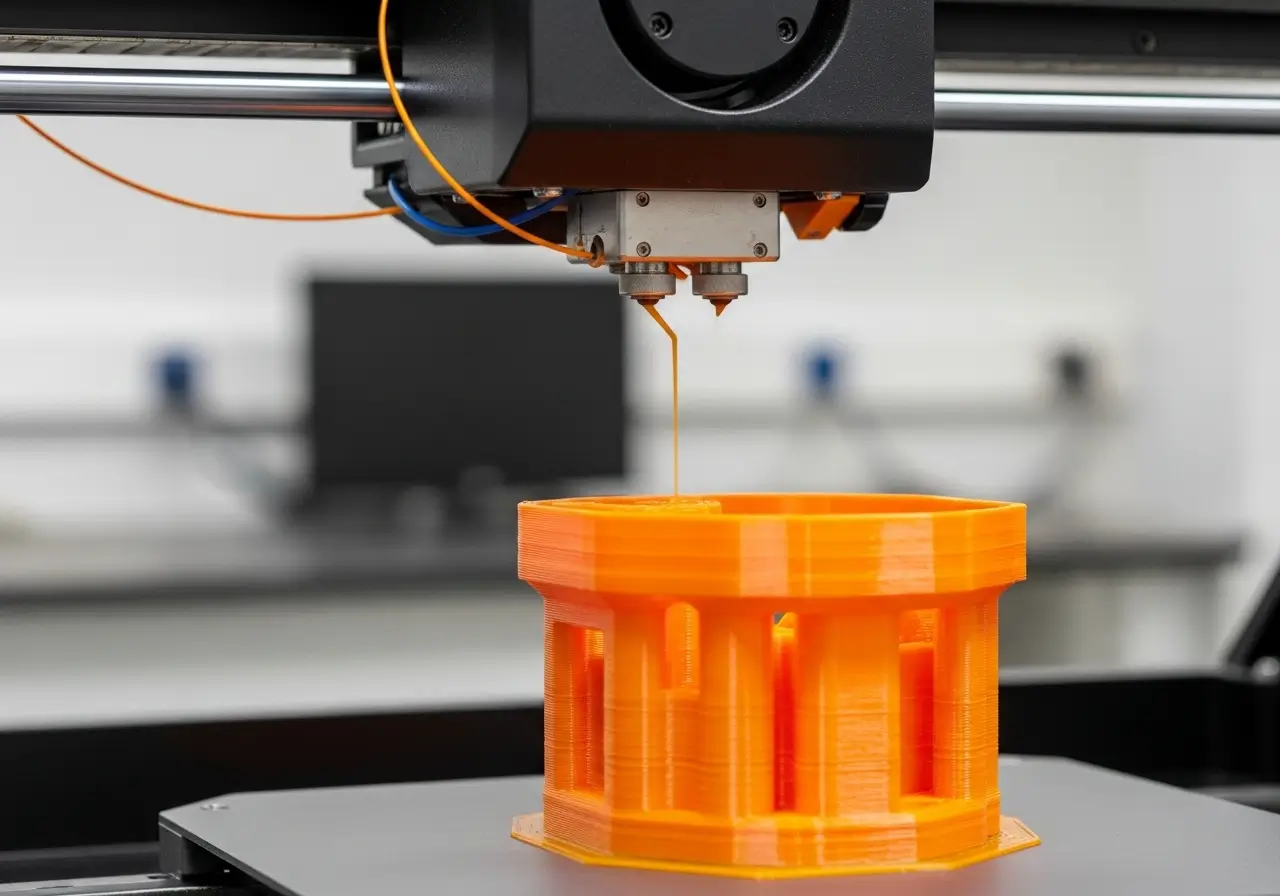

Fused Deposition Modeling (FDM)

Working process:

FDM printers work by casting thermoplastic filaments via a heated nozzle. On a build platform, The material is preserved layer by layer, and on the build platform, it cools and becomes hard to form the final object.

Materials:

In FDM printers Polylactic Acid (PLA), Acrylonitrile Butadiene Styrene(ABS), Polyethylene Terephthalate Glycol (PETG), Thermoplastic Polyurethane (TPU) Materials are Used. FDM printers are normally applied in Prototyping, educational models, custom parts, and functional end-use parts. and this is most common, Cost-effective, easy to use, wide material availability, suitable for beginners.

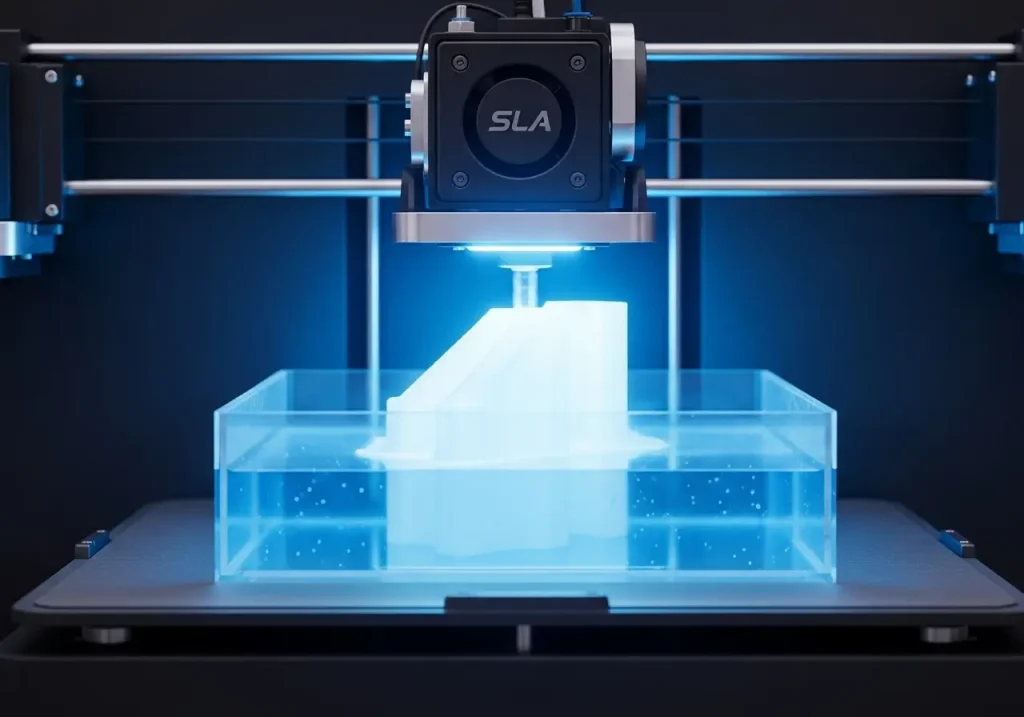

Stereolithography (SLA)

Working process:

SLA printers use a laser to make liquid resin into solid plastic. The laser particularly hardens the resin layer by layer to create the perfect object.

Materials:

In SLA printers various kinds of resins are used as material such as Standard resins, Tough resins, Flexible resins, and Castable resins. etc. Stereolithography is normally used in High-detail prototypes, dental models, and jewelry. It has smooth surface finishing advantages and wonderful detail resolution.

Selective Laser Sintering (SLS)

Working Process

Selective Laser Sintering (SLS) works by using a laser that is highly powered and able to fuse a tiny amount of polymer powder, in this process, a laser particularly sinters the powder layer by layer and forms a strong structure.

Materials

The main materials of Selective Laser Sintering (SLS) are Nylon (PA12, PA11), TPU, and Polyamide. These 3D printers are mainly used in complex geometries, Functional prototypes, end-use parts, also in low-volume production. This printer doesn’t require any further support and has excellent mechanical properties.

Digital Light Processing (DLP)

Working Process

DLP printers use digital light projectors for making photopolymer resin. a Total layer of resin is manifested to light and creates it at the same time.

Materials

In DLP Printers different kinds of photopolymer resins such as standard, tough, flexible, and castable are used. DLP Printers can make detailed prototypes, dental applications, jewelry, and miniature models. Also, DLP has features like High speed, high resolution, and excellent surface finish.

Multi Jet Fusion (MJF)

Working Process

By using an inkjet array MJF printers particularly apply fusing agents to a bed of nylon powder. Infrared light then melts the powder into a solid layer. The process is repeated layer by layer.

Materials:

The main materials of the MJF printers are Nylon (PA12, PA11), and TPU, and these printers are applied in Functional prototypes and complex geometries. It has the feature of fast production timing.

Advantages of 3D Printing

In the time of many digital technologies 3D Printing has a lot of advantages that make work and marketing processes easier for various industries to make a profit and get brand recognition in a very short time. Any industry can use these services to customize their product design and specify the needs of the products. These services are very helpful to industries like healthcare, e-commerce, garments industries, medical industries, fashion, and photography to make their work-related objects and things. This technology can make production faster, one can design a very complete part of any product or jewelry within a very short time. Also, these services are budget-friendly.

Disadvantages of 3D Printing

Although the materials for 3D printing are increasing continuously there are still some limitations and this may stick to the process of this services-related works. And compared to the traditional manufacturing system it can be quite expensive for several productions.

The Future of 3D Printing

As we can see 3D Printing services are becoming more popular in every sector, especially in the medical sector, aerospace companies, automobile sectors, and other garment industries, it will continue its innovative impact in these industries. In garment products manufacturing they can make HD and realistic photo designs even though products have complex parts that may not be possible to display by using traditional methods. In e-commerce platforms, they need more visible and high-resolution pictures to demonstrate their products and gain brand recognition, which can be achieved only by using 3D printing services. Also, it helps to minimize costs. In the future, it will introduce us to new business models and features and will create job opportunities.

Conclusion

3D Printing contributes massively within various sectors and industries, bringing innovation and making the working process fast. With the revolution of this technology industries like e-commerce and fashion, industries can customize and personalize their product manufacturing. Other industries such as medical, aerospace, and automobile will continue to take advantage of 3D printing. In the future world, the impact of this technology will be upgraded in a vast range.